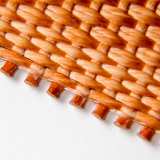

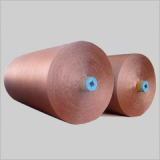

Мы занимаемся производством высокотехнологичных материалов для различных отраслей промышленности с 2002 года и успешно зарекомендовали себя на российском и международном рынках технического текстиля.

Для достижения высоких результатов компания использует производственные мощности, которые обеспечены современным высокотехнологичным оборудованием. Сегодня в производстве используется сырье мировых лидеров в отрасли технического текстиля, что гарантирует несомненное удовлетворение любых запросов клиентов.